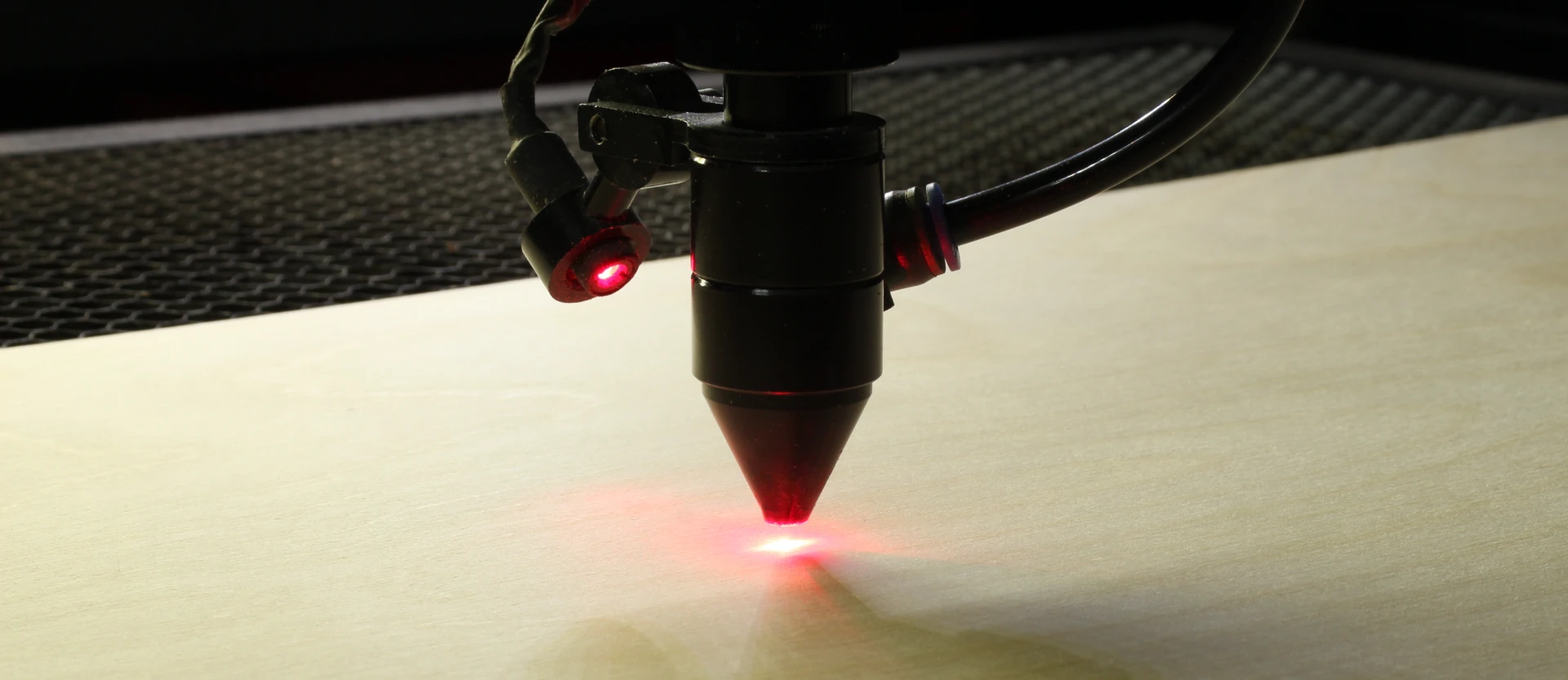

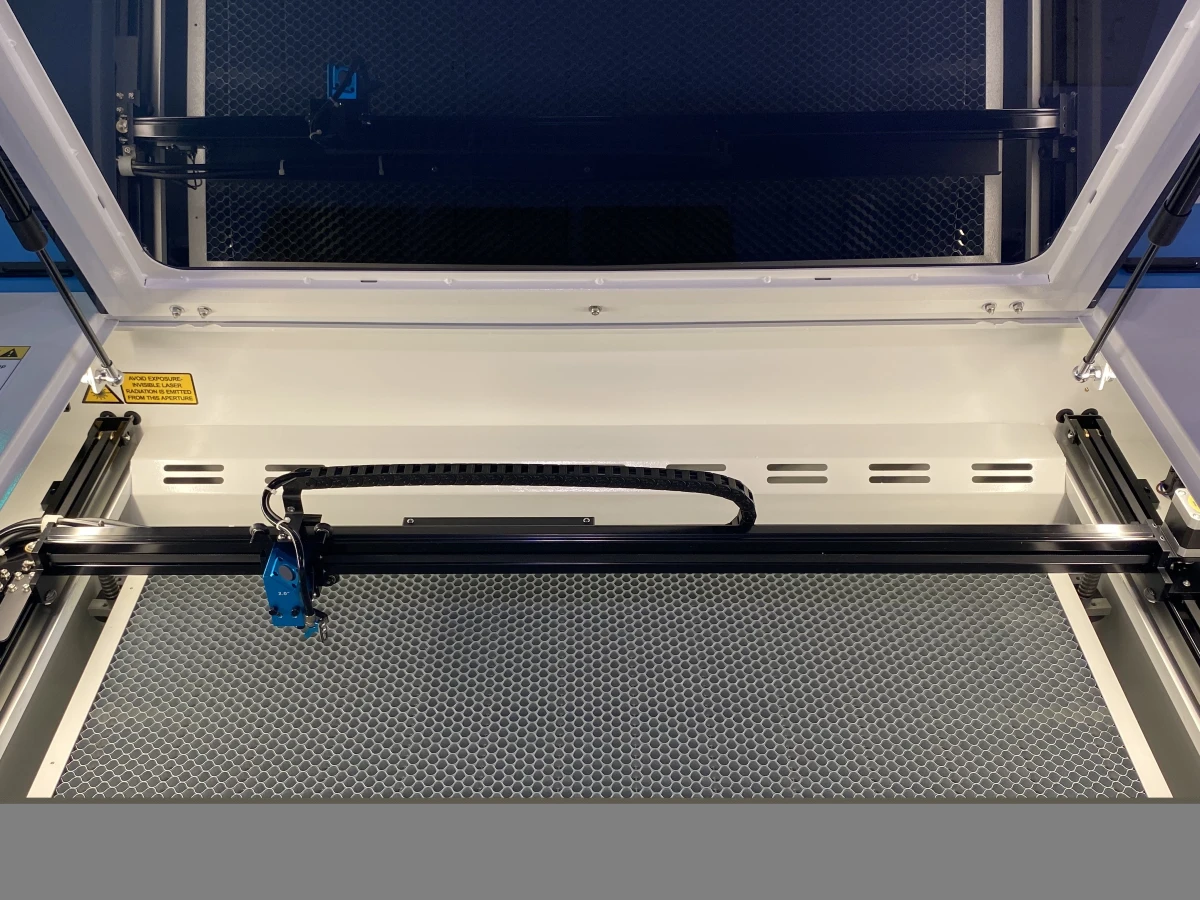

Utilizing a CNC CO2 laser we transform digital objects into physical products. Whether engraving or cutting, material is processed quickly, and precisely producing quality results.

Utilizing a CNC CO2 laser we transform digital objects into physical products. Whether engraving or cutting, material is processed quickly, and precisely producing quality results.

CNC CO2 laser systems work by generating an intense beam of infrared light, focused to a fine point on the processed material, rapidly vaporizing the material away in a precise manner. Power and speed are adjusted depending on the material and desired depth of cut.

Using this technology, we can produce industrial products for numerous applications. These applications can be split into two major categories, often with overlap.

The term laser engraving indicates that the laser vaporizes/burns material away as the laser passes over the substrate, creating depth in the engraved area. On the other hand, some materials may by better classified as being marked, since a contrasting mark can be created but there is little to no change in depth.

Laser engraving and marking are excellent methods of manufacturing placards and signage and other industrial labeling of all kinds—simple to complex.

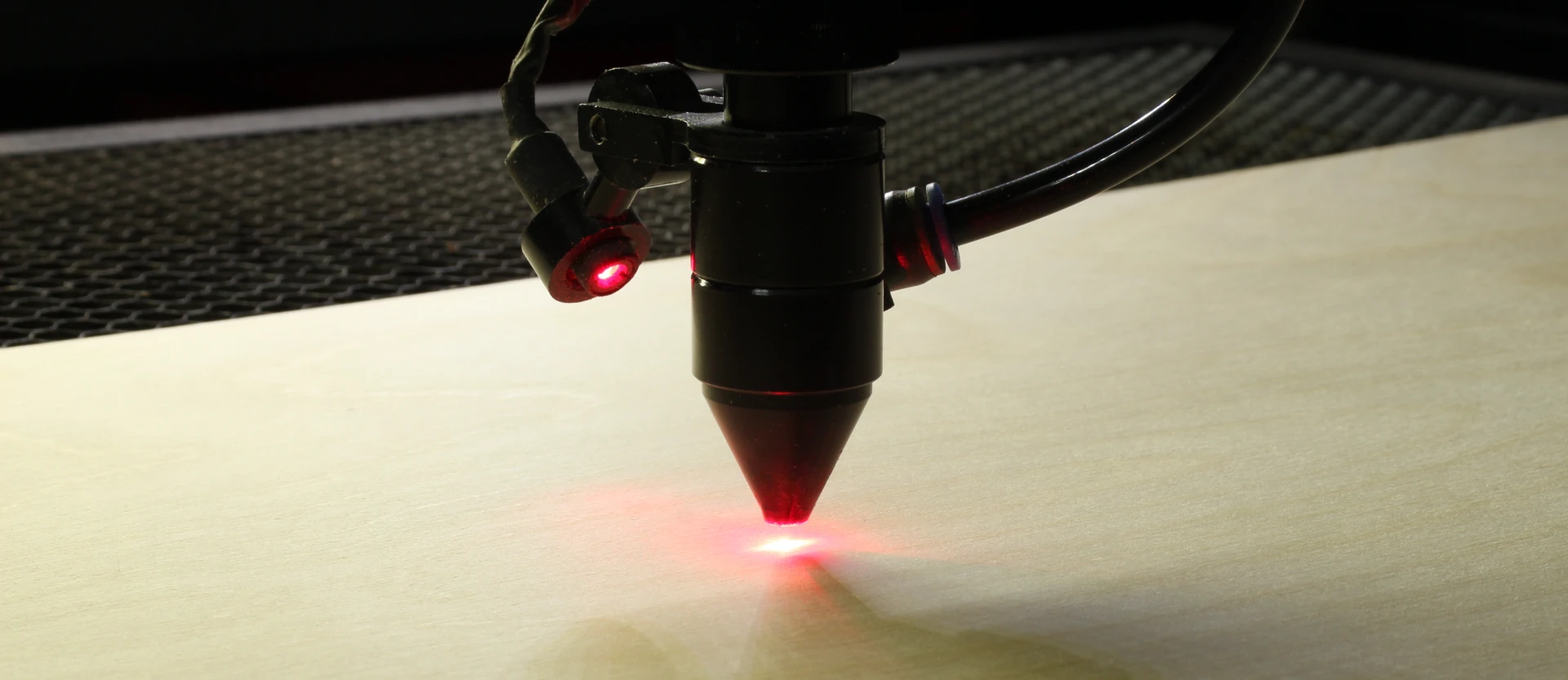

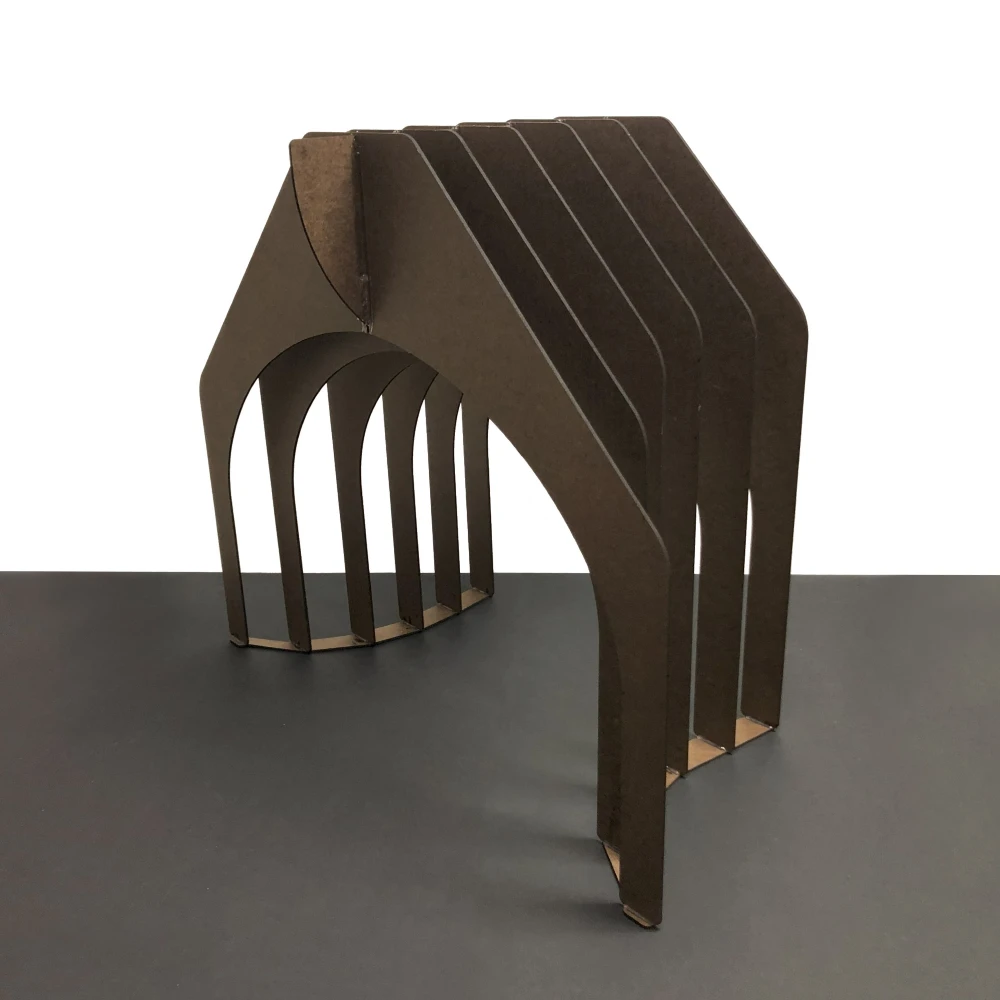

Laser cutting is self-explanatory; the laser beam penetrates through the entire depth of the material, to cut out the desired contours.

Laser cutting is a fast and economical way to manufacture 2-dimensional parts. Laser cutting may also be a good option for prototyping, before investing in more expensive manufacturing methods. Laser-cut parts can also be assembled to make 3D objects.

The versatility of CO2 lasers creates a wide range of useful applications. Here are some examples:

The applications are endless...

We currently employ a 55W CO2 laser system.

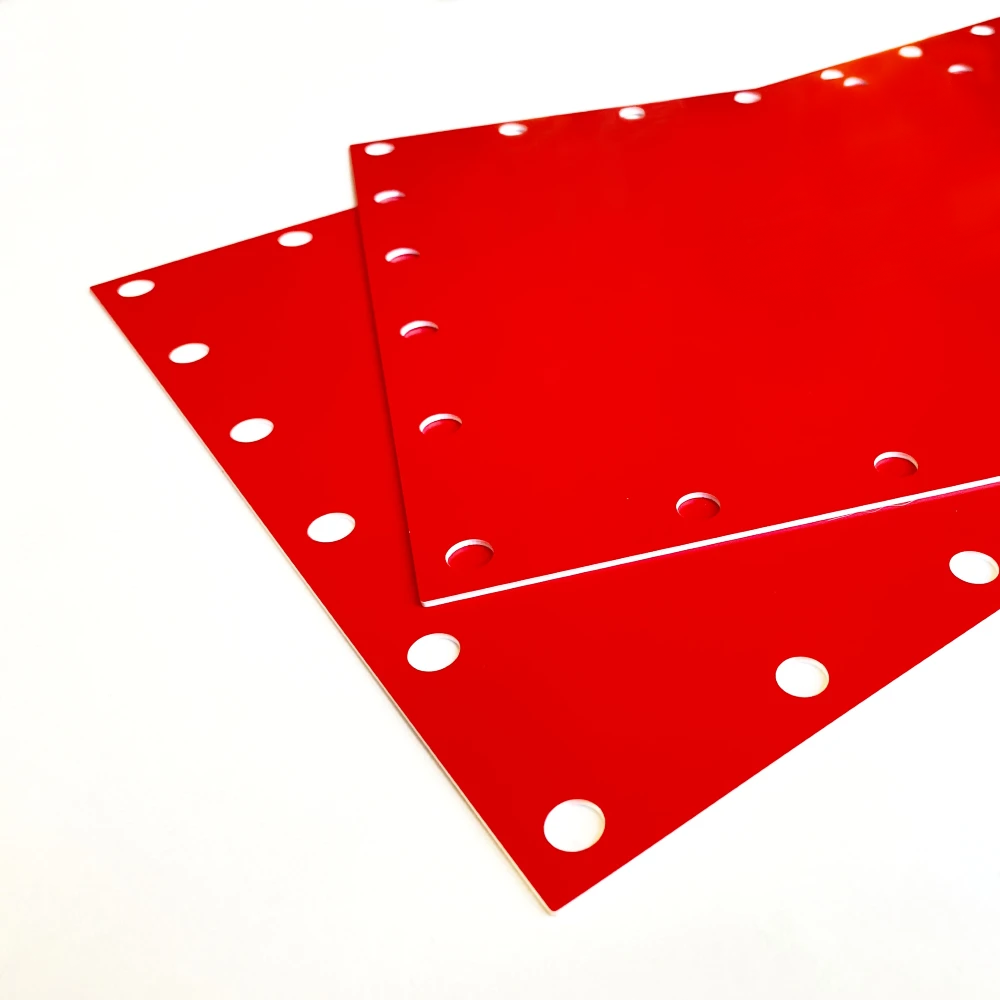

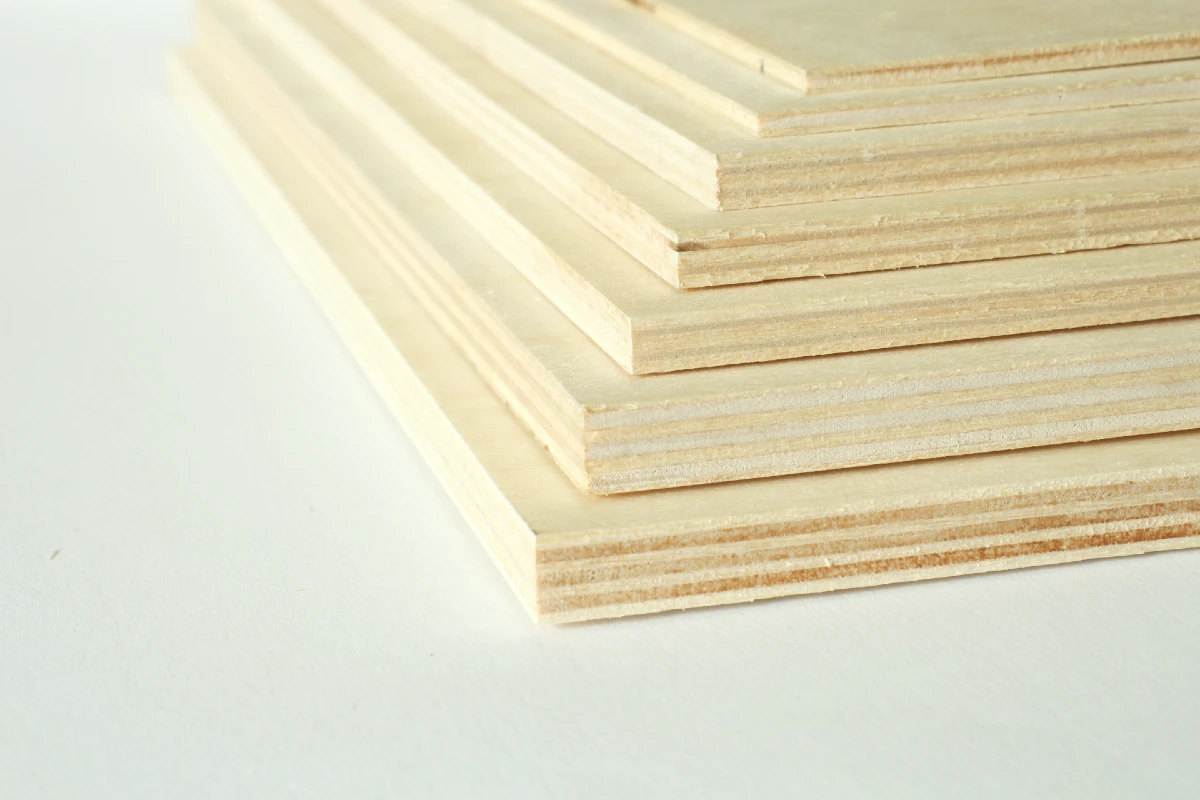

Not all materials are created equal when it comes to laser processing. Some can be engraved and cut (e.g., acrylic), while others can only be etched/marked (e.g., anodized aluminum). Some bare metals such as stainless steal or copper may be etched using an assisting marking compound. Many materials should not be laser processed at all due to toxicity, while others simply don't respond well to a CO2 laser. Check out the material compatibility table below.

| Material | Engrave/mark | Cut |

|---|---|---|

| Acrylic | ||

| Plywood | ||

| MDF | ||

| Paper | ||

| Cardboard | ||

| Anodized aluminum | ||

| Glass | ||

| Bare metals (w/ added marking compound) |

If you need a material not listed here, please contact us, and we will see what we do for your application.